Sunday, November 21, 2021

Canon EOS Remote Intervalometer

Friday, October 22, 2021

A Little Background on Yagi Antennas

I just realized that I've been going on and on about different parts of the Yagi antenna without providing much background. A document describing the Yagi antenna, or more properly a Yagi-Uda antenna, was first published in 1926. Many people are most familiar with this antenna in the form of over-the-air TV antennas that were mounted on the rooftop of nearly every house decades ago. Here's a link to a Google Doodle celebrating Yagi Hidetsugu's birthday that illustrates what I'm talking about.

https://www.google.com/doodles/hidetsugu-yagis-130th-birthday

Each of the metal cross-pieces on the antenna is called an element. There may be as few as three elements, but there can be as many as ten or even more elements. There are three types of elements. The longest element is called the reflector and it's located at the "back" of the antenna, and it redirects signals arriving from the other elements towards the "front" of the antenna. The element next to the reflector, and in the middle of the three element array, is called the driven element. It's slightly shorter than the reflector, and is split into two segments. The two segments are connected to a radio transmitter or receiver. Finally there are one or more directors that focus the radio waves into a narrow beam. The directors are shorter than the driven element, and sometimes get even shorter as more are added.

In the above sketch of a Yagi antenna, the "back" is to the left and the "front" is to the right. If the antenna's connected to a radio transmitter, the direction of greatest signal strength is to the right, or in the direction of the director. If the antenna's connected to a radio receiver, the direction of greatest sensitivity is from the right, or from the direction of the director.This trade-off in signal strength results in other desirable characteristics; for example, directionality. Because the Yagi antenna is most sensitive in one direction it's useful in applications such as wildlife tracking.

The optimizations I'm making in these blog posts are no great new discovery. I'm just starting with a reference design and exploring what happens when I vary certain design parameters in a simulation. The purpose is to give me an opportunity to play with the simulation software, and to get a more intuitive understanding of an antenna design that's always fascinated me.

Thursday, October 21, 2021

Further Optimization of Yagi Antenna Parameters

In the previous post, I documented my experiments with the spacing between elements in a three element Yagi antenna. What about the length of the antenna elements?

In a Yagi, the reflector is longer than the driven element, and the director is shorter than the driven element. In the reference design I've been using, the difference in element length was four percent in both cases. Is this optimum? In fact it appears to be. I wrote this script to explore the question:

https://github.com/umeda/nezumi/blob/master/Projects/antenna_sim/yagi_optimize_length.py

I assumed the difference in lengths to be the same in both cases, then simulated antennas with zero to ten percent difference in their lengths.

Sunday, October 10, 2021

Optimizing Yagi Design Parameters

There are so many different Yagi designs published in books, magazines, and on the web. But what's the difference between them? For a basic three-element Yagi, design parameters include the spacing, length, and diameter of the elements. Performance parameters include standing wave ratio (SWR) characteristics, gain, and front-to-back ratios. When I see a design, I wonder what the designer's goals were, and if I change one parameter, how will other parameters be affected?

I started out with the impressive National Bureau of Standards Technical Note 688, titled Yagi Antenna Design. The author built antennas and measured their performance as parameters were varied. I wanted to do something similar using NEC2 simulation software in an effort to understand the relationship between design and performance parameters. I used the PyNEC library so I could programmatically try many different combinations. Using a Python script is much more efficient than using any of the NEC2 applications, because I can simulate and compare hundreds of configurations in a matter of minutes.

Starting with one of the basic three-element Yagi designs in the technical note, I noticed that the spacing between the elements was the same, and that the spacing was one quarter of the antenna's design wavelength. What would happen if the spacing between elements remained equal, but was increased or decreased. I updated the script yagi_3_element.py to measure the forward antenna gain and plot it. And wouldn't you know it? The script predicted maximum gain at one-quarter wavelength which matched what was measured in the technical note.

Saturday, January 23, 2021

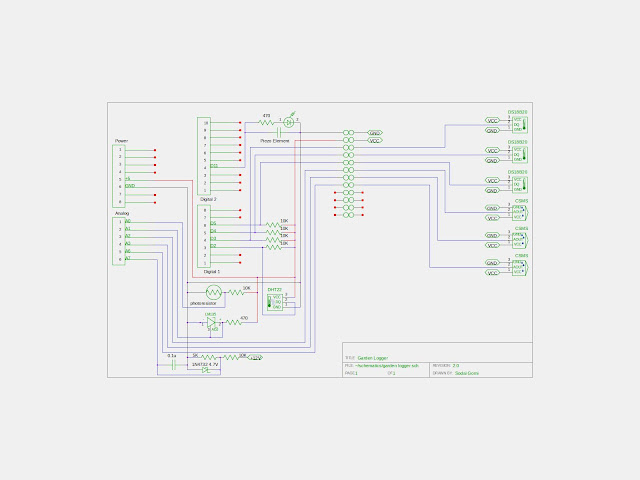

Garden Logger Schematic and Voltage Divider Script

There are a few features I want to add to the Garden Logger, but now the wiring's getting complicated. I'm adding three soil moisture sensors, a battery voltage measurement circuit, a voltage reference, and an LED with an annunciator. I need to use a CAD tool to draw the schematic, so I tried gEDA Schematic Editor. It's pretty easy to use and there is a library of user generated parts. You can also easily generate your own parts and modify existing ones. I used the symbol editor to create a soil moisture probe and a temperature/humidity sensor. Once you've created the symbol, you have to move it to /usr/share/gEDA/sym/local.

For the battery voltage measurement circuit, I needed to calculate what resistor values to use for the voltage divider. I wrote a little script to calculate this, and in the process found a neat library called "engineering_notation". The library makes it easy to display values in powers of three using the correct SI notation.

Here are the results:

Enter input voltage: 15

Enter output voltage: 5

Enter current in mA: 1

r1 value => 10kΩ

r2 value => 5kΩ

voltage => 5.0 volts

current => 1.0 milliamps

r source => 2.50kΩ

r1 power => 10.0 milliwatts

r2 power => 5.0 milliwatts

Monday, January 11, 2021

Web Server for the Garden Logger

I'd like to be able to see how the Garden Logger's doing. Is it still running? What values is it reading now?

I'd like to stick a Raspberry Pi in the bento box with the Arduino, run a web server on the Pi, and have have the Pi serve up web pages showing the logger's status; and maybe even control which channels are scanned at what speed.

I was going to develop it on a Pi Zero W, using VSCode via SSH. No dice - VSCode didn't support the Pi Zero's Processor. Same thing with RasPi 2. It does work with a RasPi 3, but I didn't have any to spare, so I wrote the code on my Linux Mint workstation.

I thought it would be great if logger could send a nice JSON package across to the Pi, but it was better to keep things simple on the Arduino and to put those smarts into the web server. So for now, every time the Arduino writes data to the SD card, it also sends a string of data channel names followed by a string of the data from those channels.

The first thing to do is to install the serial and web server libraries. For some reason, I needed to "pip uninstall" the serial library, then "pip install" the pyserial library. I "pip install"ed the Flask library for the web server.

After connecting the Arduino to a USB port, the sever app needs to find the port that the Arduino's attached to. This is the code snippet I used. It's hard coded to use a specific "Seeeduino", so the process is that the list of hardware IDs needs to be printed using the first two lines in the code snippet, then after the right ID is determined, it gets hardcoded into the server app.

I used this tutorial as a starting point for learning Flask

After I got the example working I needed to start a thread running that would wait asynchronously for data from the Arduino, then parse it, and save it into a global variable for the web server.

The next step was to start the web server. Here's where I hit a problem. When I started it in the VSCode IDE, it was bringing up a second instance of the logger monitor thread. I was really stumped until I came across a web posting that said debug must be disabled on the server. I changed that, and the problem was fixed!

Now the final step was to get the data into a Jinja2 template for display. With a few more lines of code, I can now monitor the Garden Logger from anywhere on my network!

Saturday, January 9, 2021

Adding an External Hard Drive with Samba to a Raspberry Pi

I started with an out-of-the-box 4TB Western Digital Blue drive. I put it into a Sabrent enclosure, powered it up and plugged it in. First step is to find the drive:

pi@raspberry:/mnt$ sudo lsblk -o UUID,NAME,FSTYPE,SIZE,MOUNTPOINT,LABEL,MODEL

UUID NAME FSTYPE SIZE MOUNTPOINT LABEL MODEL

sda 3.7T WDC_WD40EZRZ-22GXCB0

mmcblk0 3.7G

4AD7-B4D5 ├─mmcblk0p1 vfat 256M /boot boot

2887d26c-6ae7-449d-9701-c5a4018755b0 └─mmcblk0p2 ext4 3.4G / rootfs

Next, some directories like the user home directory and the non-existent printer directories were showing up on some Samba clients like Macintosh and AppleTV VLC Player. The solution was to comment out the following sections in /etc/samba/smb.conf: